With a desire to enable manufacturers to experience the benefits of high-quality 3D metal printing at the best price possible, Xact Metal aims to change the perception that additive manufacturing is only for capital-rich companies.

We’re proud of our extensive network of sales partners that support our customers locally, from the initial application discussions to post-installation services.

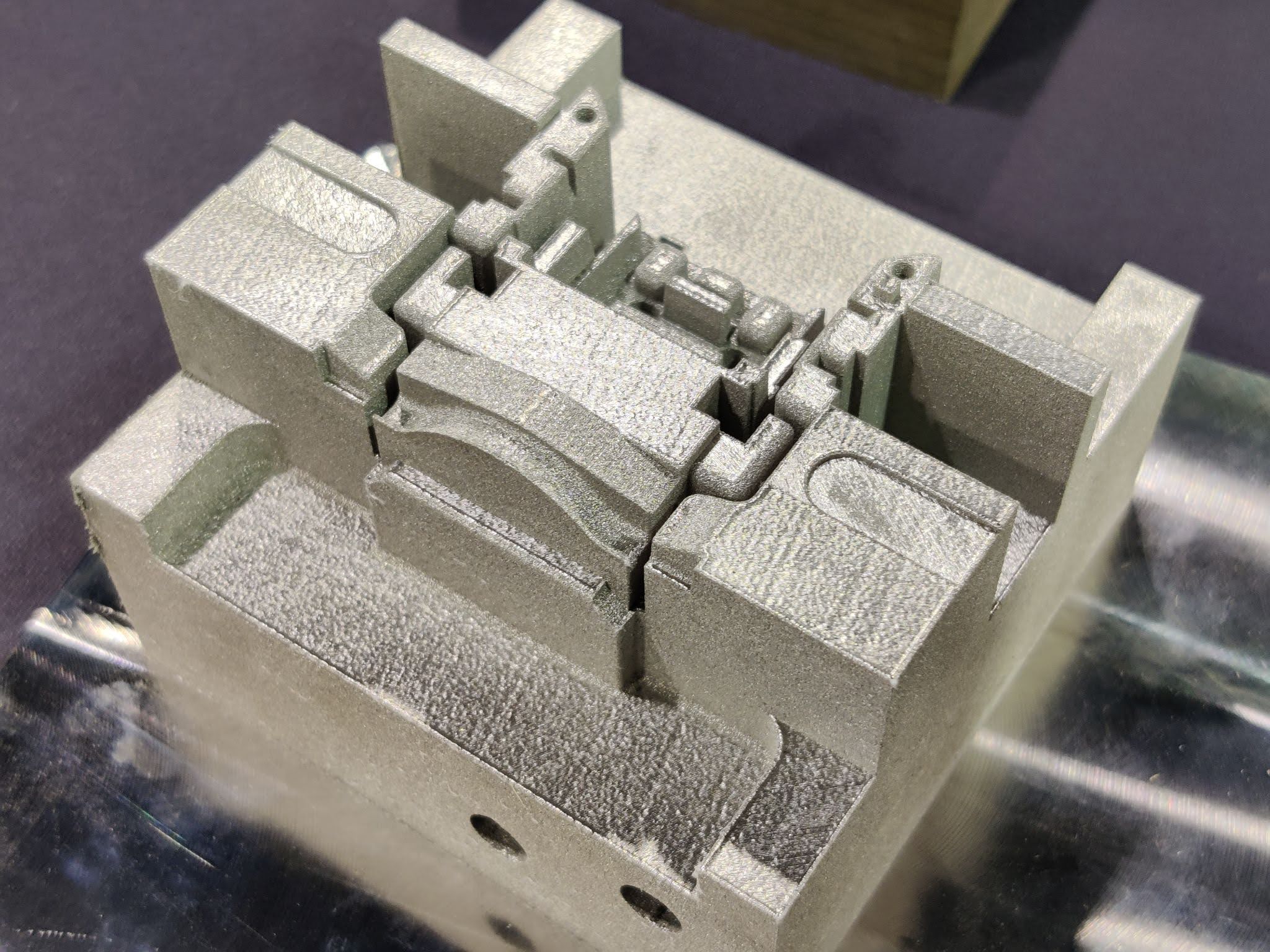

Xact Metal partners with leading material producers to offer high quality, certified and proven materials, including stainless and tool steels, super alloys, copper, titanium and aluminum.

Xact Metal partners with leaders in the industry to provide software solutions that are intuitive and modern, allowing for simple machine setup, control and monitoring.

Together with our sales partners, our services include local customer support, preventive maintenance, spare parts and powder, and more.

The way we see it, additive manufacturing is another tool in your toolbox with a range of capabilities and the potential to improve your current way of doing things.